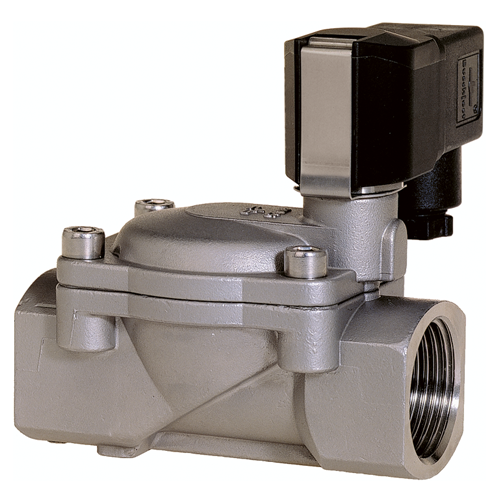

Indirect solenoid valves use the differential pressure of the media over the valve ports in order to open and close. Often, indirect solenoids require a minimum differential pressure of 0.5 bar to operate efficiently in the environment. However, this may vary depending on the brand of valve. Indirect acting solenoid valves operate through a rubber membrane, often called a diaphragm, which separates inlet and outlet ports. The diaphragm contains a small hole which allows media to flow to the upper compartment. Above the membrane, there is a spring which ensures the valve remains closed. When the valve is energised, the pilot orifice is opened, causing the pressure above the membrane to drop. The pressure difference on both sides of the membrane means the diaphragm is lifted and media can flow from the inlet port to the outlet port.

Get in touch

- +44(0)1704 898980

- sales@mgacontrols.co.uk

- MGA Controls Ltd

Unit 6, Swordfish Business Park

Off Higgins Lane, Burscough

Lancashire, L40 8JW

Need help?

Our team of technical experts are trained on the intricate details of our product offering, but also can also boast many years worth of industry and application experience. Allow us to understand your problems and help you overcome them by recommending innovative, efficient and cost-effective solutions from our portfolio of World leading manufacturers.