Pneumatic cylinders, also known as pneumatic actuators, operate by using the force of compressed air against a moving piston to create mechanical movement. Pneumatic cylinders are specified depending on the mass of the load being moved, the distance it is to be moved over and the time required to move the load.

Single acting and double acting pneumatic cylinders are the common options available. In single-acting pneumatic cylinders, air forces the piston against a spring which returns the cylinder to its default position when the air is removed. In double-acting pneumatic cylinders, air is used to push the piston one way and to return the cylinder to its default position. Air is applied on the opposite side of the piston while on the original side and the air is allowed to exhaust.

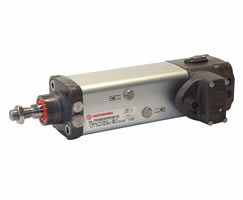

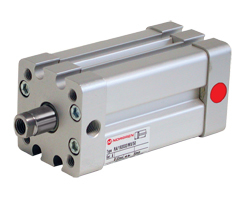

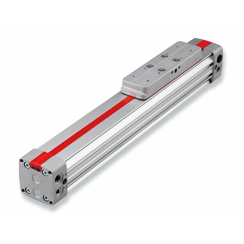

As pneumatic cylinder suppliers, MGA Controls can provide a range of ISO or VDMA standard cylinders in a variety of different materials depending on the application. We can offer rodless pneumatic cylinders and rotary actuators. Our range also includes innovative products including the IMI Norgren IVAC integrated valve and actuator range which offers the pneumatic cylinder and pilot control valve in a single, compact and efficient unit.

MGA Controls has developed long-standing partnerships with the top suppliers in the process field, such as IMI Norgren & Konan. These relationships allow us to supply an extensive range of high-quality pneumatic actuators to the market at competitive prices.

We can supply pneumatic cylinders for use in a wide range of industries, such as process, pharmaceutical, food and beverage, packaging, automotive, nuclear, power and water. MGA Controls can supply cylinders to suit most application needs, however standard or specialised.

To complete our range of cylinders, we can also supply cylinder accessories and mountings, such as seal kits, brackets and limit switches to suit any application.

For assistance in specifying the most appropriate single or double acting pneumatic cylinders, please call our technical team on +44 (0)1704 898980 or email sales@mgacontrols.co.uk.